Cheddar is a popular type of cheese which originated in the United Kingdom in the village of Cheddar. Typical original cheddar cheese characteristics are the hard texture, orange colour and tangy flavour. Cheddar cheese types nowadays can vary from a soft texture, mild flavour to the original tangy flavour with a hard texture. In most cases melting salts are added to the cheddar cheese to bring it in line with the preferences of fast-food manufacturers, whose products require a type of cheddar cheese which melts easily. Cheddaring machines like the DMC cheese machine and Tetra Pak cheddaring machine are designed for producing these type of soft cheeses.

This type of cheddaring machines need to remove the whey by draining the soft cheddar cheese (curds), the whey needs to escape while the curds remain on the cheddaring machine belt. Piles of small curds knit together and acidify after the draining stage, this process is called cheddaring. The curd is cut in smaller pieces at the end of the cheddering belt once the curd is fused together during the draining process.

Mozzarella, pasta filata and other soft cheeses

Not only cheddar cheeses but also soft and wet cheeses like mozzarella and pasta filata are processed and drained in a similar way. Most of those cheeses need a continuous manufacturing system to drain and produce high volumes of cheese. Value’s in terms PH value, moisture and salt content need to be consistent during this process, the system needs to distribute the salt evenly across the belt in proportion to the depth of the actual soft cheese (curd). This is extremely important to guarantee a continuous high quality output.

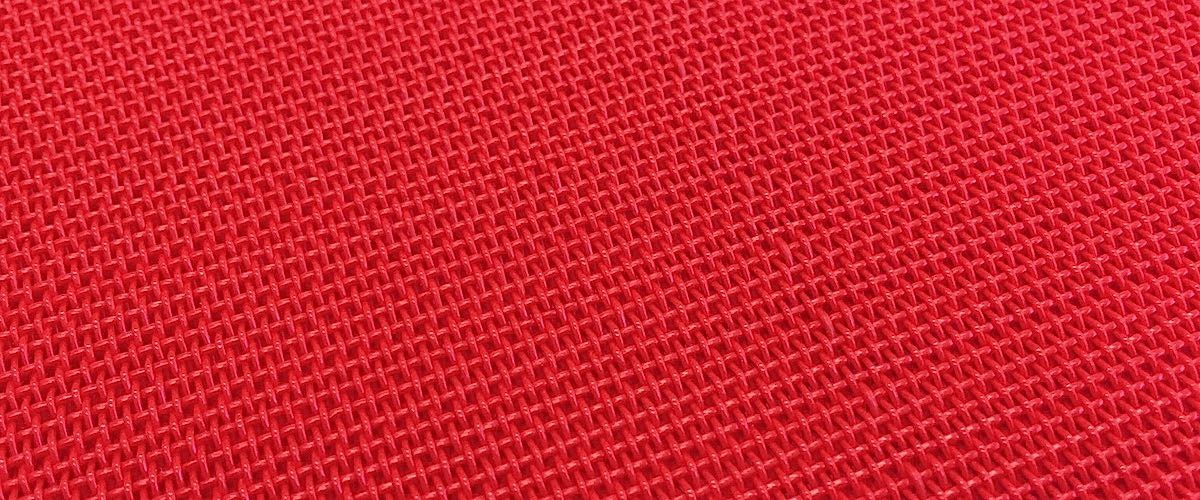

Cheese draining belts

Cheddaring machine belts are usually woven monofilament polypropylene belts or woven polyester belts which have a high liquid permeability to drain the cheese curds proportionally. Wiremeshes.eu | Drenth Holland manufactures two different colours (red and transparent) of double layered monofilament polypropylene wire mesh belts specifically designed and developed for cheddaring machines and other types of soft and wet cheese draining machines. The red type of belt is preferred when food factories want to detect possible contamination in case of unforeseen damage which could occur very occasionally during the process. Polypropylene wire mesh is recommended rather than polyester due to the high resistance against chemicals, the polypropylene belts can be cleaned with highly aggressive chemicals during CIP (cleaning in process) without losing durability unlike polyester belts.