A filtermat spray dryer system is an alternative solution to fluid bed dryers and drum dryers. These machines are used in processes where food needs to be dried into powder form. However, many dairy products or other kind of food ingredients are difficult to spray dry due the high level of fat, carbohydrate or protein contents. A filtermat spray dryer installation with a high quality and durable wire cloth belt is engineered to handle these kind of products with ease.

Filtermat spray dryer installations are built for endurance and to provide a high quality product output without too much spillage in economic terms. Synthetic wire mesh belts are built to withstand severe conditions like humidity and hot air in order to process moist powder. The high volume capacity and the flexibility of product choice are also huge benefits of the filtermat spray dryer installations. Filtermat spray dry installations are also capable of processing food slowly at a lower temperature than the more common spray dry installations can provide, this is necessary to process very sticky food. Other conventional spray dry systems are not always capable of providing continuous quality in the long term and need to be cleaned frequently.

Filtermat spray dryer in action

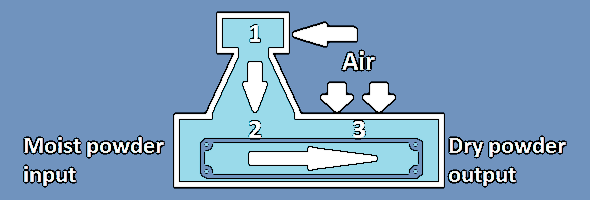

The filtermat spray dryer consists of various nozzles, fans, heaters, a drying chamber and a wire cloth belt. Processing sticky food towards powder form works as follows:

- The nozzles spray semi-dried food downwards into the drying chamber on the wire cloth belt, the nozzles are supported by air streams to prevent contact between the drying chamber wall and the food.

- The sticky semi-dried food falls downwards and is formed as a mat of moist powder scattered equally on the wire cloth belt.

- Within the next two stages the moist powder is dried by passing a hot air stream and a cooling down air stream. The wire mesh belt has great air permeability which enables the air to pass through the belt and the powder. The humidity is very low at the last cooling down stage whereas the powder is dry and ready for further processing.

Together with other European institutes, Drenth Holland bv developed wire cloth belts especially for these kind of filtermat spray dry installations. These wire cloth belts enhance the output of filtermat installations, as these belts provide the lowest possible product spillage, great air permeability and superb strength and stability.